SEDIMENTATION PLANT

3P HYDROSHARK

Full flow treatment without separating structure

Areas 500 m² – 35,000 m² Combination structures unlimited

Volume flows up to 875 l/s for combination structures unlimited.

Qmax up to 1,100 l/s

POLLUTANTS

Trash and debris*

Microplastic**

Total suspended solids (TSS)***

Mineral-oil hydrocarbons (MOH)

*** Particle size d50= 122μm

REMOVAL

> 99%

> 99%

> 94%

> 98%

OVERVIEW HYDROSHARK / TECHNICAL DATA

3P Hydroshark

750

FOR INSTALLATION IN A

CONCRETE SHAFT DN 800

Connectable area full flow treatment

Category II*:

1,200 m²

Maximum treatment flow rate [l/s]**

30

Maximum hydrolic flow [l/s]***

50

Max. Nominal connection diameter DN****

200

3P Hydroshark 1.000

FOR INSTALLATION IN A

CONCRETE SHAFT DN 1000

Connectable area full flow treatment

Category II*:

2,400 m²

Maximum treatment flow rate [l/s]**

60

Maximum hydrolic flow [l/s]***

115

Max. Nominal connection diameter DN****

300

3P Hydroshark 1.500

FOR INSTALLATION IN A

CONCRETE SHAFT DN 1500

Connectable area full flow treatment

Category II*:

5,000 m²

Maximum treatment flow rate [l/s]**

167

Maximum hydrolic flow [l/s]***

228

Max. Nominal connection diameter DN****

500

3P Hydroshark 2.000

FOR INSTALLATION IN A

CONCRETE SHAFT DN 2000

Connectable area full flow treatment

Category II*:

10,000 m²

Maximum treatment flow rate [l/s]**

250

Maximum hydrolic flow [l/s]***

416

Max. Nominal connection diameter DN****

600

3P Hydroshark 2.500

FOR INSTALLATION IN A

CONCRETE SHAFT DN 2500

Connectable area full flow treatment

Category II*:

20,000 m²

Maximum treatment flow rate [l/s]**

500

Maximum hydrolic flow [l/s]***

832

Max. Nominal connection diameter DN****

700

3P Hydroshark 3.000

FOR INSTALLATION IN A

CONCRETE SHAFT DN 3000

Connectable area full flow treatment

Category II*:

35,000 m²

Maximum treatment flow rate [l/s]**

875

Maximum hydrolic flow [l/s]***

1,100

Max. Nominal connection diameter DN****

700

* DN 1,500; AFS63 retention 48.0 %, IKT-tested on 19.04.2024

* DN 1,000; AFS63 retention 47.4 %, IKT-tested on 19.04.2024

* DN 2,000; AFS63 retention 48.7 %, tested on 22.04.2024

* DN 2,500; AFS63 retention 47.3 %, tested on 24.07.2024

* DN 3.000; AFS63 retention 47,51 %, tested on 01.10.2024

*** Rated rainfall rmax = 250 l/(s – ha)

**** Pipe diameter depends on the slope, can be individually adjusted

PLANNING CERTAINTY THROUGH APPROVALS

DESIGN ACCORDING TO

DWA-A102

DESIGN ACCORDING TO

DWA-M 153

TESTED IN ACCORDANCE WITH

TRENNERLASS NRW

LANUV-

LIST NRW

MEASUREMENT TOOL

FOR THE TREATMENT OF RAINWATER FOR YOUR PROPERTY IN ACCORDANCE WITH DWA-A 102/BWK-A 3-2

Determination of the appropriate treatment plant for discharge into surface waters.

TENDER SPECIFICATIONS &

DRAWINGS

Request your

tender texts and

drawings!

PLANNING TOOLS

Individual, needs-oriented &

up-to-date information

BIM DATA

Building information modeling

(Building Information Modelling, BIM) for

the provision of 3D and 2D data,

tender texts and other

information for your construction projects.

YOU NEED PROFESSIONAL

SUPPORT OR

HAVE QUESTIONS FOR US?

Jonas Bitterling, M. Eng.

Project Engineer

Tel +49 (0) 7334 92460-12

Mail bitterling@3ptechnik.de

Daniel Betschner,

Master Professional of

Technical Management (CCI)

Project Engineer

Tel +49 (0) 7334 92460-32

Mail betschner@3ptechnik.de

REFERENCES

ZUGSPITZE

ECONOMIC ENTERPRISES HAGEN

LOGISTICS CENTER DISTRICT OF BIBERACH

DEGGINGEN SPORTS GROUND

THOROUGHFARE EBERSBACH

AMAZON GIENGEN

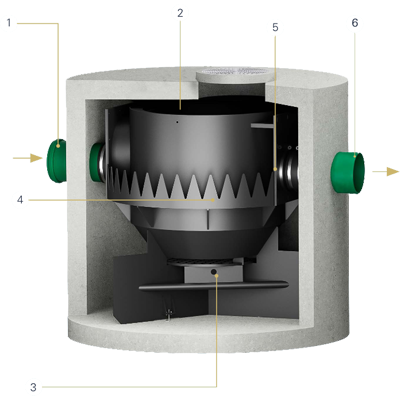

FUNCTIONAL PRINCIPLE

①

The water flows in tangentially in the middle of the hydrodynamic separator.

②

Solids settle to the bottom, floating matter remains on the water surface.

③

The solids are collected in the sludge trap, which is hydraulically separated from the treatment chamber by flow breakers and a grating to prevent remobilization.

④

The water rises evenly up the side walls.

⑤

The purified water is collected in an annular chamber via a serrated weir and then transported to the outlet.

⑥

The water runs off.

3D MODELL

THE HYDROSHARK

THE SEDIMENTATION PLANT SHOWING TEETH

The Hydroshark sedimentation system reliably removes filterable

substances (TSS) from stormwater runoff. It thus protects bodies of water and

infiltration systems.

Whereas in previous years, sewage treatment plants or agriculture were often the cause of water pollution, today it is rainwater discharges from polluted areas such as heavily trafficked traffic areas, industrial areas, parking lots or even metal roofs.

The loads are very different and are divided into categories in the DWA worksheets, for example. Depending on the sensitivity of the water, the need for treatment is then derived. Discharges into groundwater are viewed more critically, as groundwater is our drinking water resource of tomorrow.

For large areas of several hectares, for example, centralized treatment systems such as rainwater clarifiers or retention soil filters can be used for stormwater treatment. Decentralized treatment plants have become established for smaller areas, inner-city areas with little parking space or hotspots of pollution, e.g. at traffic light intersections. Different process technologies are used depending on the substance or substance group.

APPLICATION AREAS

Traffic areas

Roof surfaces

Special applications

Physical treatment of precipitation water.

Underground system, therefore no space required above ground.

Removal of solids (TSS).

No height offset between inlet and outlet.

Easy control and maintenance.

Different sizes.

No blocking possible.