SEDIMENTATION PLANT

3P HYDROSHARK VARIO

Full flow treatment without separating element.

Areas 500 m² – 35.000 m² Combination structures unlimited.

Volume flows up to 875 l/s Combination structures unlimited.

PLANNING CERTAINTY THROUGH APPROVALS

ECTRACTION VIA

DWA-A102

ECTRACTION VIA

DWA-M153

TESTED

SEPERATION EDICT NRW

LANUV-

LIST NRW

MEASUREMENT TOOL

FOR THE TREATMENT OF RAINWATER FOR YOUR PROPERTY IN ACCORDANCE WITH DWA-A 102/BWK-A 3-2

Determination of the appropriate treatment plant for discharge into surface waters.

TENDER SPECIFICATIONS &

DRAWINGS

Request your

tender texts and

drawings!

PLANNING TOOLS

Individual, needs-oriented &

up-to-date information

BIM DATA

Building information modeling

(Building Information Modelling, BIM) for

the provision of 3D and 2D data,

tender texts and other

information for your construction projects.

YOU NEED PROFESSIONAL

SUPPORT OR

HAVE QUESTIONS FOR US?

Jonas Bitterling, M. Eng.

Project Engineer

Tel +49 (0) 7334 92460-12

Mail bitterling@3ptechnik.de

Daniel Betschner,

Master Professional of

Technical Management (CCI)

Project Engineer

Tel +49 (0) 7334 92460-32

Mail betschner@3ptechnik.de

REFERENCES

DEVELOPMENT

KÖNIGSBRONNER FELD

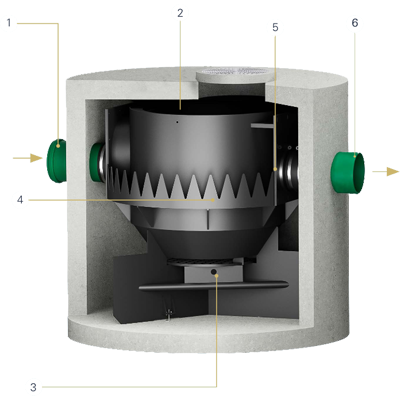

FUNCTIONAL PRINCIPLE

①

The water flows tangentially into the center of the hydrodynamic separator.

②

Solids settle to the bottom, floating matter remains on the water surface.

③

The solids are collected in the sludge trap, which is hydraulically separated from the treatment chamber by flow breakers and a grating to prevent remobilization.

④

The water rises evenly up the side walls.

⑤

The purified water is collected in an annular chamber via a serrated weir and then transported to the outlet.

⑥

The water runs off.

THE HYDROSHARK VARIO

AS VARIABLE AND INDIVIDUAL AS YOUR PROJECT

The Vario product variant has been added to the Hydroshark sedimentation system series. With flexibly positionable inlet and outlet, our compact, highly efficient rainwater treatment systems can now be installed in an even more versatile, faster and space-saving way.

When planning systems for the stormwater treatment of traffic areas, contractors are often confronted with complicated or cramped installation situations. Sealed surfaces or additional pipes for gas, electricity or communication, for example, make installation more difficult. What’s more, in many cases, existing lines are still being used. With the standard opposite arrangement of the inlet and outlet at a 180° angle, complex adjustments are often necessary to adapt the installation to the structural conditions.

With the Hydroshark Vario, the connections can now be planned and manufactured at any angle. The customer defines the exact position of the inlets and outlets. We then produce the Hydroshark system exactly according to the customer’s specifications. This reduces the time required for work on site and complicated installation situations can be solved much more easily. In addition to the flexible positioning of the inlet and outlet, we now offer prefabricated connections ex works for all common pipe materials, for example plastics, GRP pipes, reinforced concrete, cast iron or vitrified clay. This also contributes to simpler planning and faster installation. No further adaptation work is required on site for existing pipes that will continue to be used.

APPLICATION AREAS

Traffic areas

Roof surfaces

Special applications

Variable angles for inlet and outlet.

Various pipe dimensions.

Physical treatment of precipitation water.

Removal of solids (TSS).

Underground system, therefore no space required above ground.

No height offset between inlet and outlet.

Easy control and maintenance.

Different sizes.

No blocking possible.