FILTRATION SYSTEM

3P HYDROSYSTEM 1.500

For areas with heavy traffic.

For metal roofs.

OVERVIEW HYDROSYSTEM / TECHNICAL DATA

heavy traffic

FOR HEAVILY LOADED

TRAFFIC AREAS DTV > 15,000

Connectable area:

1,600 m²

Flow rate:

Q = 16 l/s

metal

FOR METAL ROOF SURFACES

(COPPER, ZINC, LEAD)

Connectable area:

1,300 m²

Flow rate:

Q = 13 l/s

PLANNING CERTAINTY THROUGH APPROVALS

DIBT

APPROVAL

LFU METAL ROOF

APPROVAL

LANUV-LIST

NRW

VSA PERFORMANCE

AUDIT

EXTRACTION VIA

DWA-A 102

EXTRACTION VIA

DWA-M 153

EXTRACTION VIA

DWA-A 138

TENDER SPECIFICATIONS &

DRAWINGS

Request your

tender texts and

drawings!

PLANNING TOOLS

Individual, needs-oriented &

up-to-date information

BIM DATA

Building information modeling

(Building Information Modelling, BIM) for

the provision of 3D and 2D data,

tender texts and other

information for your construction projects.

YOU NEED PROFESSIONAL

SUPPORT OR

HAVE QUESTIONS FOR US?

Jonas Bitterling, M. Eng.

Project Engineer

Tel +49 (0) 7334 92460-12

Mail bitterling@3ptechnik.de

Daniel Betschner,

Master Professional of

Technical Management (CCI)

Project Engineer

Tel +49 (0) 7334 92460-32

Mail betschner@3ptechnik.de

REFERENCES

GFA NEUSS

INDUSTRIAL BUILDING

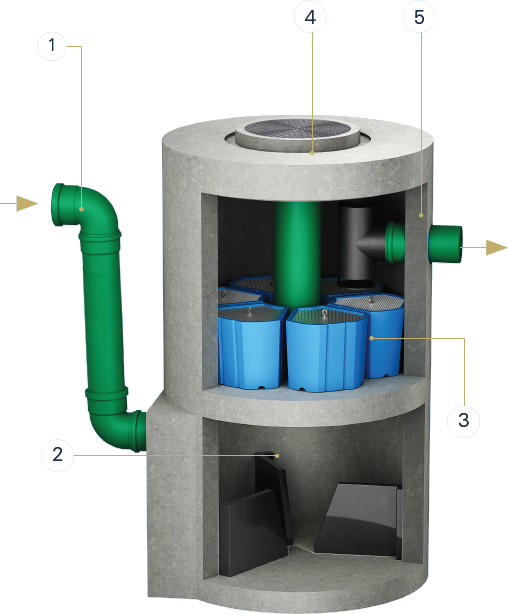

FUNCTIONAL PRINCIPLE

①

The stormwater from the area to be drained is discharged at the lower end of the shaft. The deflection aid deflects the water tangentially.

②

These are collected via an opening in the lower part of the cleaning shaft in a sludge trap with flow breakers under the system. The sludge trap is vacuumed out at intervals.

③

There are six filter elements in the middle of the manhole. These are used to filter the fines in an upflow process and a large proportion of the dissolved pollutants are precipitated and adsorbed. The filter can be backwashed from above and can be easily replaced if it becomes completely clogged.

④

The filter elements can be easily removed via the existing shaft opening.

⑤

The clean water is located above the filter elements. It passes through an oil barrier and then flows via the drain into the seepage system or a surface water body.

3D MODELL

HYDROSYSTEM 1.500

HIGH PERFORMANCE ON LARGE AREAS

The Hydrosystem 1.500 is installed in a concrete shaft with an internal diameter of DN 1500 at the factory.

A hydrodynamic separator causes the sedimentation of solids in a radial flow regime characterized by secondary flows. The effect of the separator causes the solids to enter the flow-calmed sludge trap located below the flow breaker. The 6 filter elements are located above the separator chamber. The water passes through the six filter elements in an upflow process. The system removes pollutants such as heavy metals, mineral oil hydrocarbons and polycyclic aromatic hydrocarbons from the rainwater. It also binds nutrients such as phosphates. The quality of the purified water is so high that it can be discharged directly into the infiltration system or any receiving waters.

The height difference between the inlet and outlet is only 25 cm. As the system is installed under the traffic surface, it does not require any additional space on the property or in the street. The treatment system can be used for traffic areas such as parking lots and roads of all traffic loads, industrial areas and metal roofs. Six different filter cartridges are available for this purpose.

FILTER VARIANTS

heavy traffic

For heavily loaded

traffic areas

metal

For metal roof surfaces

Cleaning of rainwater runoff from

traffic areas, industrial areas and metal roofs.

Shaft system, no space required on the surface.

Low height offset.

Easy control and maintenance.